Universal Cleaning Liquid PLUS

for all cartridges

and inkjet print-heads

|

|

||

マニュアルダウンロード |

Download Instructions |

Scarica le Istruzioni |

|

|

||

|

Cleaning Liquid is a liquid designed for removing ink residue and impurities from print head nozzles to restore proper functioning and ensure their durability over time. |

||

Recommendations• Use the cleaning liquid at room temperature to facilitate the melting of impurities on the print head (dried ink, micro-paper residues) |

|

|

|

|

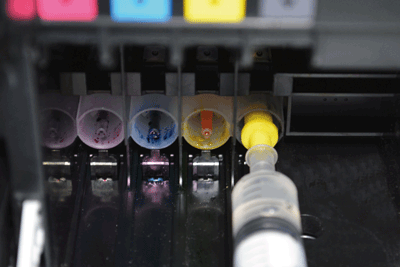

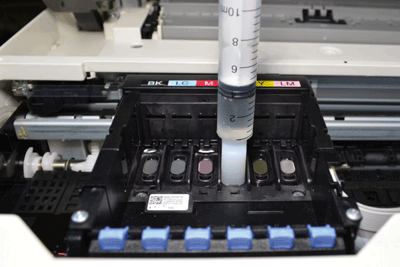

Cleaning of FIXED and REMOVABLE heads• Place the printer carriage in “cartridge replacement” mode |

|

|

|

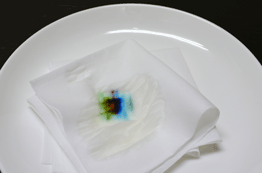

| Place paper towel(s) under the print head |

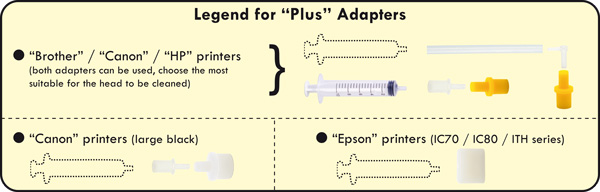

Head Cleaning (“Brother” and “HP” type) |

|

|

| Head Cleaning “Canon” type (black) | Head Cleaning “Canon” type (colors) |

|

|

| Head Cleaning “Epson” type | Head Cleaning “Epson” type IC70 / IC80 / ITH series |

|

|

| Legend for “Plus” Adapters | |

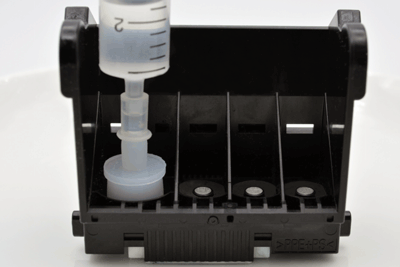

Cleaning a MONO-BLOCK head• Remove the cartridge to be cleaned from the printer |

|

|

|

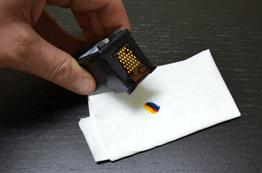

| Cleaning a mono-block cartridge “Canon”, “HP”, “Lexmark” type | |

|

|

| Drying and visual testing | |

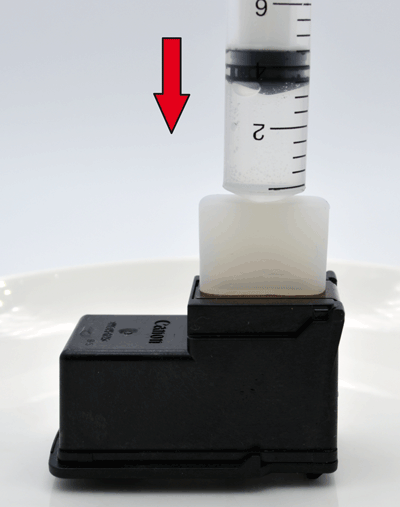

Cleaning of MONO-BLOCK head through adapter• Remove the cartridge to be cleaned from the printer

|

|

|

|

| 1 - Cleaning Liquid injection |

2 - Suction of Cleaning Liquid and excess air (priming) |

Test pagesAfter the cleaning operations, we recommend printing some test pages

|

|

WIKI-PRINTpl (picoliter) Print head Printing technology

Differences between “FIXED”, “MONO-BLOCK” and “REMOVABLE” The mono-block head is supplied as part of a replaceable ink cartridge. Finally, the removable head is a combination of the two previous techniques: the print head can easily be removed from the printer (usually by lifting a lever/hook) and the ink cartridges can be changed when needed. |

|