WIKI-PRINT

pl (picoliter)

It is the unit of measurement used that defines the size of a single drop of ink ejected from a single print nozzle.

1pl = 1/1,000,000,000,000 liters

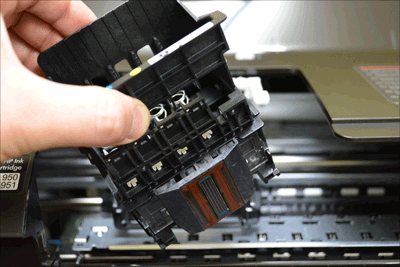

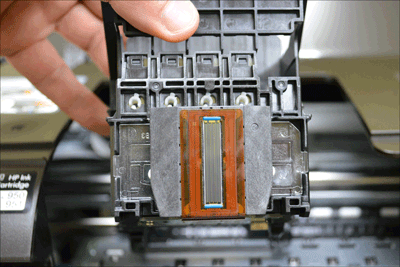

Print head

The print head is the heart of the printer. It physically “sprinkles” tiny drops of ink that will form the final print.

The latest generation of inkjet printers can spray droplets as small as 1.5 pl through over 1,000 tiny nozzles!!! These 1,000+ nozzles form the “print head”.

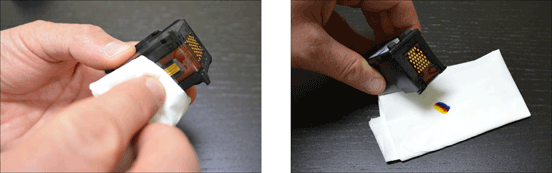

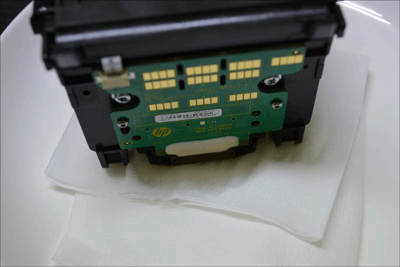

Therefore, it is important that you choose a high quality ink that will not damage the printable print head over time (or after many recharges) when refilling the cartridges.

superInk is here for this with its latest line of inks!

Printing technology

There are essentially two technologies used for the operation of the print heads:

• Thermal (or Bubble-Jet)

At each nozzle a resistor is positioned through which current pulses are passed; at each impulse the resistor warms up to a few hundred degrees in a few microseconds and generates a vapor bubble on contact with the ink. Expansion of the latter causes the expulsion of the drop by the nozzle above; this is the most widespread technology in the Home/Office field and is mainly used by HP (Hewlett-Packard), Canon and Lexmark.

• Piezoelectric

Below each nozzle there is a channel surrounded by a piezoelectric crystal; an electric impulse causes the crystal to change shape and consequently cause pressure in the duct and forces the ejection of the ink. This is the technology used principally by Brother and Epson for their inkjet printers.

Differences between “FIXED”, “MONO-BLOCK” and “REMOVABLE”

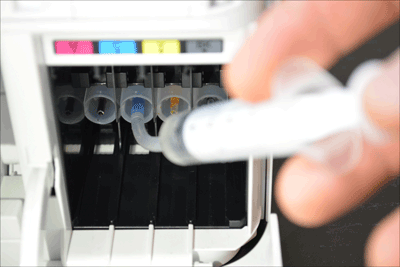

The fixed head is inserted directly into the printer and is designed to last for the entire life cycle of the printer.

This considerably reduces maintenance costs since the head does not have to be replaced each time the ink runs out. In addition, printing quality is generally better and does not require any calibration.

Unfortunately, in case of head damage, the replacement cost (if replacement is possible) makes the operation extremely costly, forcing the user to be more likely to buy a new printer.

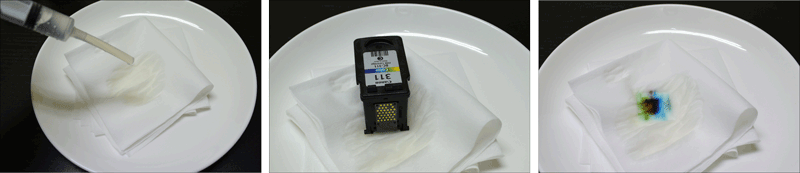

The mono-block head is supplied as part of a replaceable ink cartridge.

Each time a cartridge (ink cartridge) is exhausted, the entire cartridge and print head are replaced with a new one. This increases the cost of consumables and makes it more difficult to make a high-precision head at a reasonable cost, but also means that if the print head is damaged or clogged, the problem can be solved easily: you buy a new cartridge (complete with head) and the printer will print as good as new!

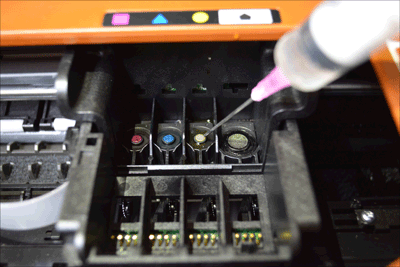

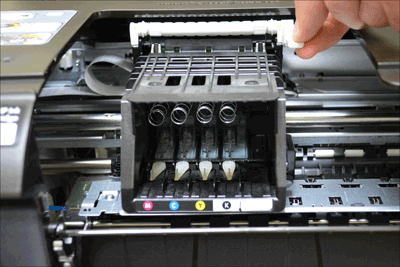

Finally, the removable head is a combination of the two previous techniques: the print head can easily be removed from the printer (usually by lifting a lever/hook) and the ink cartridges can be changed when needed.

Many Canon printers and some HP printers use this kind of mixed technology. In this case, the print heads are designed to last for the entire life of the printer, but can be replaced more easily by the user (and more economically) if they are clogged.

|